Functional Compounds

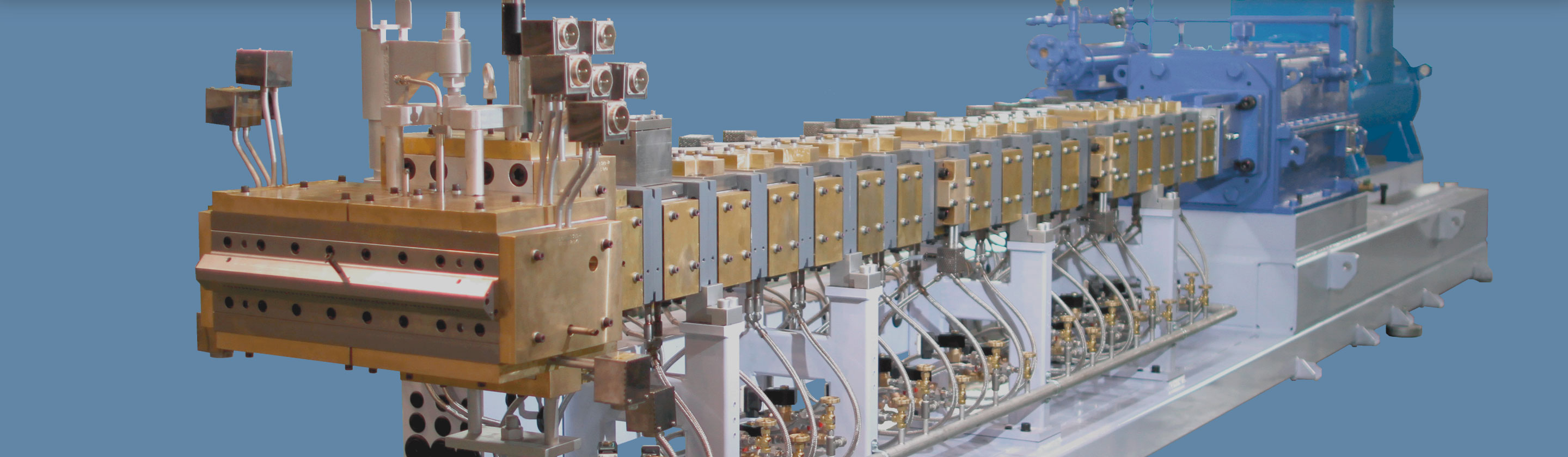

Our Compound Equipment

The advantages of our compound manufacturing facility lie in its ability to stably supply a wide variety of raw materials and its superior granulation technology for low-viscosity kneaded products. By utilizing our equipment, it is possible to knead and process raw materials that were difficult to process with conventional extruders. We propose the development of compound products with new functionalities. In addition, our mixing technology enables us to increase the blending ratio of functional materials, thereby reducing the amount of additives required for masterbatch products and contributing to cost reductions for our customers.

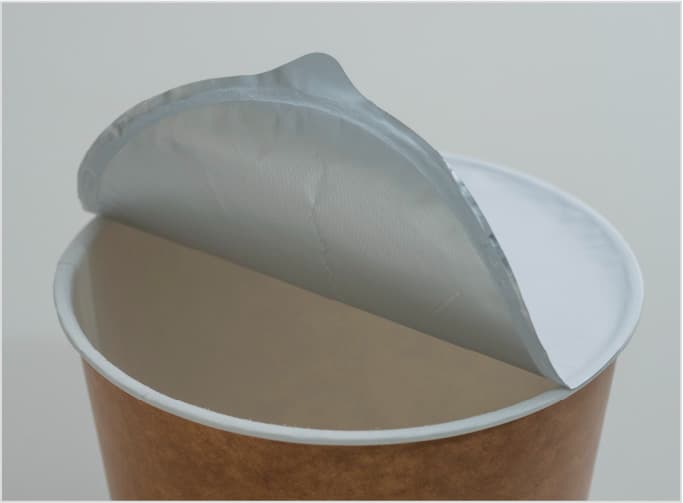

- Hot melt adhesives mainly used as sealing layers in easy-peelable films for food packaging lids (top seals)

- Compatible with extrusion lamination, inflation, and roll coater processes

- Adhere to PP, PS. PE, as well as difficult substrates like PET and metal

- Suitable for industrial applications when extruded onto substrates such as paper and nonwoven fabrics

Applications: Easy-peelable food lids, heat seal tapes, aluminum foil coatings for food containers, medical packaging materials

Products

- Masterbatch Solutions

-

Sales of masterbatches made from various plastics, terpene resins, and functional materials. We offer contract manufacturing using our technology for mixing diverse raw materials, high-flow granulation technology, and formulation proposals.

- Compound Solutions

-

Manufacturing and sales of functional compound products such as plastic modifiers, compatibilizers, and coating adhesion promoters. We also produce polymer blends/alloys products and offer contract manufacturing using kneading and granulation technologies.

Applications: Moisture-proofing agents for general-purpose plastics, Adhesive agents for elastic materials, Adhesive agents for general-purpose plastics, Anti-fogging agents for polyester resins, Surface modification agents for olefin resins, Compatibilizer for various plastic materials

- Synthetic rubber-based hot melt adhesives available in a range from low to high tack

- Selectable based on intended use and application conditions

Applications: Plastics, beverage packaging, building materials, automotive parts

Products

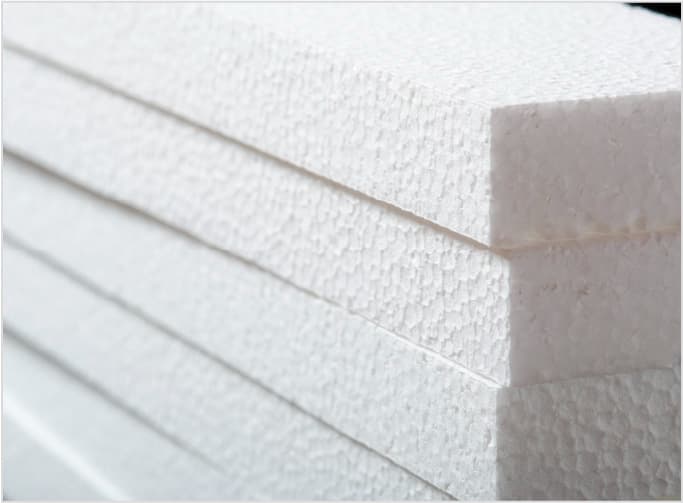

- Ideal for bonding paper materials such as cardboard and cartons

- Includes heat-stable and stringing-resistant variants that improve working environments

Applications: Packaging, anti-slip coatings, cardboard, coated paper, expanded PS

Products

- Hot melt adhesives for air filters mainly composed of olefin polymers

- Suitable for filter assembly applications such as fixing spacers and frame materials.

Applications: Air filter pleats, frame materials

Products

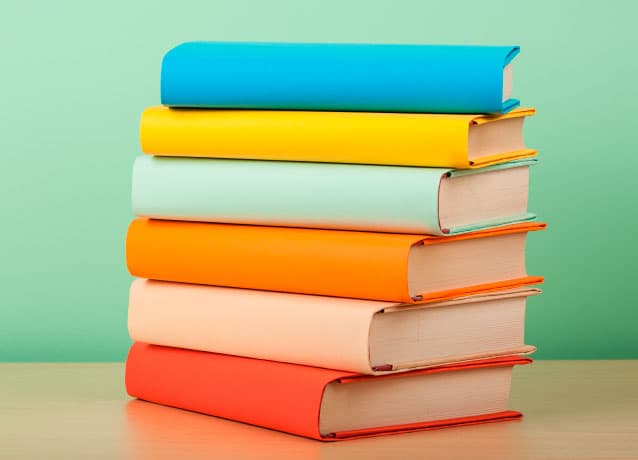

- Our laminated products are used for surface protection and gloss finishing of publications and various catalogs

- Produced using proprietary hot melt adhesives (solvent-free), making them suitable for eco-friendly applications such as solvent elimination, energy saving, and zero waste, contributing to consumer convenience

Applications: Publications, shopping bags, paper containers

Products for Publications

Hirotack Series